What Makes the Process of Silk Screening so Unique

You see that silk screening is special because you can feel the prints. The Process of Silk Screening uses thick ink layers. This makes colors bright and bold. These colors last longer than other ways. Each print feels like art. Skilled people make each one with care. They add layers slowly. This gives rich and textured results. Every piece is different and special.

- The textile industry will lead the screen printing market in 2025. This is because more clothes are made and people want custom designs.

- Asia Pacific will have a 37.3% market share in 2025. This is because it is strong in making textiles and electronics.

- North America will grow the fastest with a 26.1% market share in 2025. This is because it makes high-quality products and uses new technology.

Key Takeaways

- Silk screening makes prints you can feel. The ink sits on top and feels raised. Each print looks special and creative.

- The process uses layers of colors. Every color needs its own screen. This makes the print bright and textured.

- Silk screening does not cost much for big orders. It is great for making custom shirts and items for events.

- You can use this method on many things. It works on fabric, wood, and glass. This lets you make many kinds of projects.

- You must get the screen ready the right way. You also need to cure the print. This helps the print stay nice and last after many washes.

What Makes Silk Screening Unique

Tactile and Textured Prints

When you touch a silk screened print, you notice something special. The ink sits on top of the material, creating a raised surface. This makes the print feel different from other printing methods. Your fingers can sense the texture because of the way the ink interacts with the fabric. Scientists have found that your skin’s friction against the fabric helps you feel the roughness and softness of the print. The brain receives signals from your fingertips and tells you about the surface.

Tip: If you want to test the quality of a silk screened shirt, run your fingers over the design. You will feel the thickness and texture that show the print’s durability.

A study with 19 volunteers showed that people can tell the difference between fabrics by touch. The friction between your skin and the print helps you judge the quality. This tactile experience is one reason why many people choose silk screening for custom apparel and luxury packaging.

- Silk screen printing produces bright, durable prints on many materials.

- Each color in a design needs a separate screen, which adds to the texture and feel.

| Findings | Description |

|---|---|

| Friction Coefficient | Scientists measured how your skin slides over different fabrics. |

| Tactile Perception | People in the study could feel differences in roughness and softness. |

| Study Participants | 19 volunteers helped researchers understand how touch affects perception. |

Hands-On Artistry

You play a big role in the Process of Silk Screening. Artists and printmakers do not just press a button. They create the original image, prepare each stencil, and mix the inks by hand. Every color in your design gets its own screen. You must line up each screen perfectly to make sure the colors match. This careful work means that every print is a little different.

- You start by making the artwork.

- You create a separate stencil for each color.

- You attach each stencil to its own screen.

- You mix inks to match your design.

- You print each color in the right order.

Artists say that silk screening is different from machine printing. Machines make copies that look exactly the same. When you use silk screening, you add your own touch and creativity. Each print becomes a unique piece of art.

- Silk screen printing is known for its versatility and vibrancy in color.

- It works well for many projects, such as custom shirts and special packaging.

Color Layering Technique

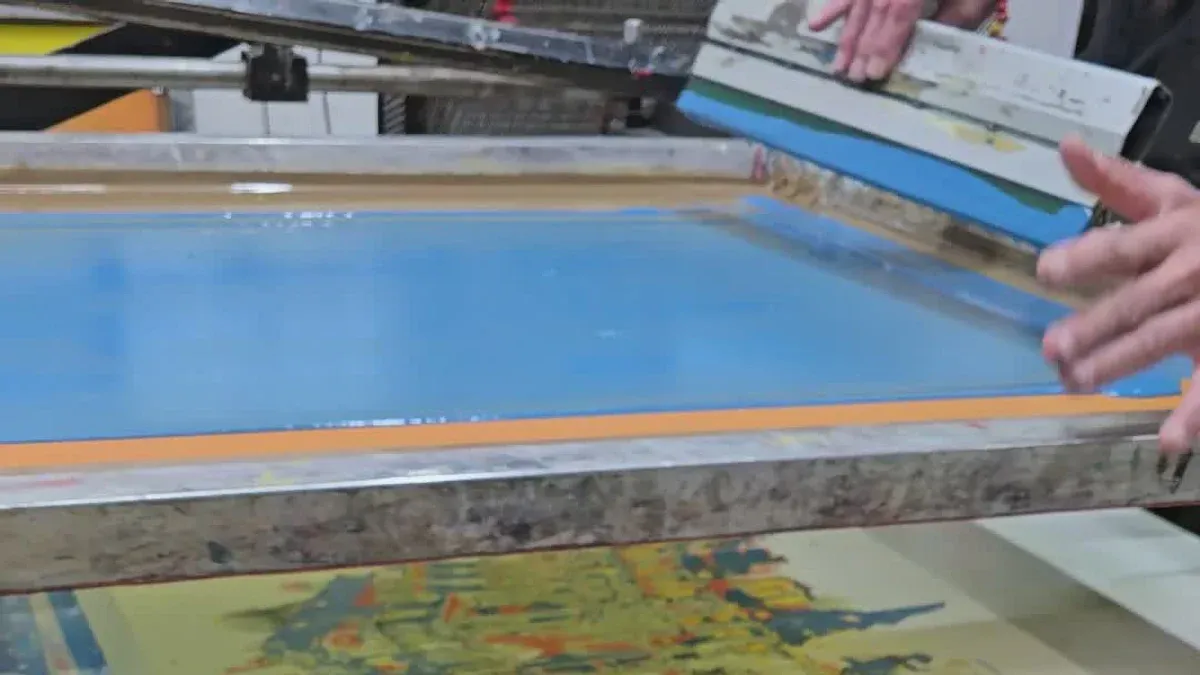

Color layering is a key part of the Process of Silk Screening. You use a different screen for each color. You print one color at a time, letting each layer dry before adding the next. This method lets you create bright, multi-colored images that stand out.

- Strategic use of color makes your design more attractive.

- Color choices can change how people feel about your product. For example, blue can make people feel calm, while orange can give energy.

- You can match colors to your brand, making your products easy to recognize.

To get the best results, you need to pay attention to details:

- Leave part of the image in every screen for perfect alignment.

- Use tools like a vinyl cutter for sharp edges.

- Wash the screen well to remove any extra emulsion.

| Technique/Consideration | Description |

|---|---|

| Artwork Preparation | Make sure your design is ready for color layering. |

| Registration | Line up each color carefully to avoid mistakes. |

| Split Screen Printing | Print several colors at once if you use the right spacing and dividers. |

You can see that silk screening stands out because of its hands-on approach, textured prints, and creative color layering. These features make every print unique and memorable.

The Process of Silk Screening

The Process of Silk Screening involves several important steps. Each stage requires attention to detail and hands-on skill. You will see how every part of the process adds to the quality and uniqueness of the final print.

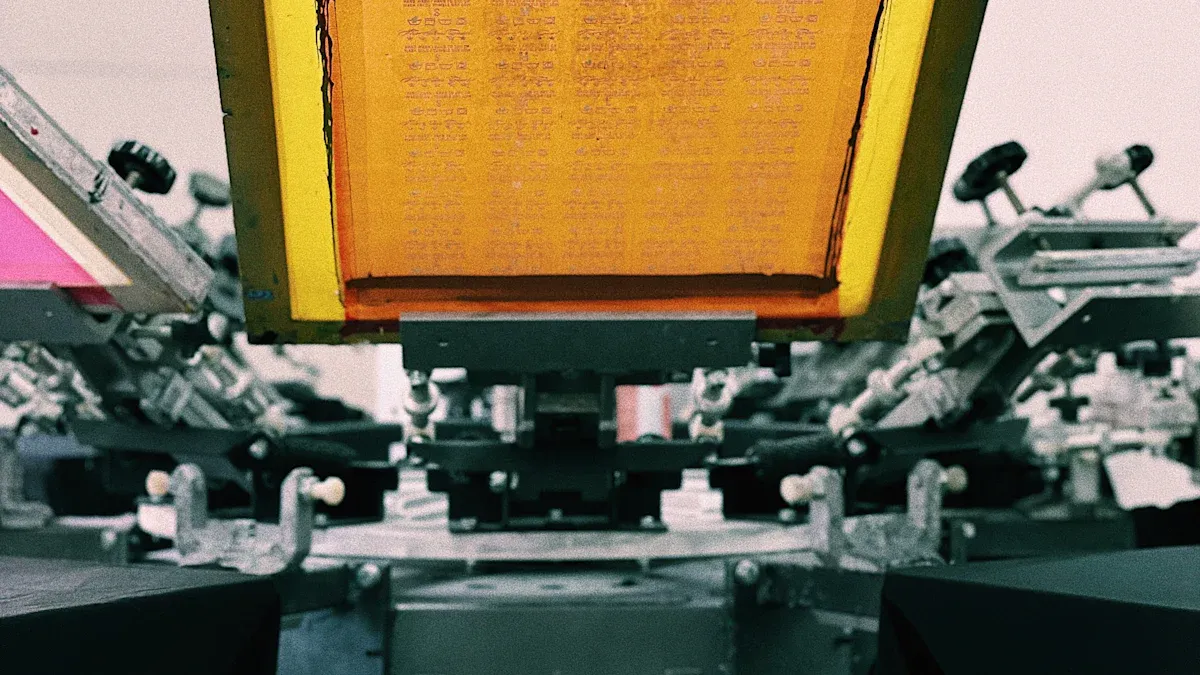

Screen Preparation

You begin by gathering all the materials you need. These include a silkscreen frame, mesh, photo emulsion, squeegee, ink, and your chosen substrate, such as a T-shirt or poster. You must clean the mesh carefully to remove any dust or oil. This helps the emulsion stick well and prevents flaws in your print.

Next, you coat the mesh with a thin layer of photo emulsion. You let it dry in a dark space. The emulsion is sensitive to light, so you must avoid bright areas during this step. The quality of your screen affects the sharpness and detail of your design.

| Category | Details |

|---|---|

| Substrate Preparation | Clean and prepare the surface for better ink adhesion. |

| Screen Creation | Choose mesh count based on design detail. |

| Ink Systems | Select ink type for the material and finish you want. |

You can see that careful screen preparation sets the foundation for the entire Process of Silk Screening. If you rush this step, you may face problems like bleeding or mesh stains later.

Tip: Always check your screen tension with a tension meter. This helps you get crisp and even prints.

Emulsion and Exposure

After your screen dries, you move to the emulsion and exposure stage. You place your design, printed on transparency film, over the screen. Then, you expose the screen to a strong light source. The light hardens the emulsion where it touches the clear parts of your design. The areas blocked by the design stay soft.

This step uses science. Photo-reactive chemicals in the emulsion react to actinic light. Chromate and dichromate chemicals help the emulsion harden quickly and evenly. After exposure, you wash the screen with water. The soft emulsion washes away, leaving open spaces for ink to pass through.

| Principle | Description |

|---|---|

| Photo-reactive chemicals | Harden when exposed to light, creating the stencil. |

| Actinic light | Activates the hardening process in the emulsion. |

| Chromate/dichromate | Enhance the photo-reactive properties for sharper stencils. |

You must expose the screen for the right amount of time. If you underexpose, the emulsion may break down during printing. If you overexpose, the design may not wash out cleanly. This stage gives you the sharp lines and fine details that make silk screening stand out.

Printing and Curing

Now you are ready to print. You place your prepared screen over the substrate. You pour ink onto the screen and use a squeegee to pull the ink across the mesh. The ink passes through the open areas of the stencil, transferring your design onto the material. For multi-color designs, you repeat this step with a new screen for each color, letting each layer dry before adding the next.

The type of ink you choose affects the look and feel of your print. Plastisol ink gives you bold, durable prints. Water-based ink soaks into the fabric for a softer touch. Discharge ink removes the fabric color and replaces it with a new pigment, which works well for dark materials.

The final step is curing. You heat the printed item to bond the ink to the fabric. Most inks cure at about 320°F. Proper curing makes your print last longer and prevents peeling or cracking. If you do not cure the ink enough, it stays sticky and may wash off. If you over-cure, the print can become brittle.

Note: Always follow the ink manufacturer’s instructions for curing. This ensures your prints stay vibrant and durable.

| Challenge | Solution |

|---|---|

| Bleeding | Use the right amount of ink and secure the substrate. |

| Mesh Stains | Clean screens after each use. |

| Incorrect Ink Usage | Match ink to substrate and cure properly. |

| Screen Tension Issues | Check and adjust tension regularly. |

| Emulsion Breakdown | Expose and cure emulsion correctly. |

The Process of Silk Screening gives you control at every stage. You can adjust pressure, ink type, and curing time to get the results you want. This hands-on approach is what makes silk screening both an art and a science.

Benefits of Silk Screening

Vibrancy and Durability

Silk screening gives you prints that look bold and last long. The ink stays on top of the fabric, so colors stay bright after many washes. This method is great for designs that need to pop, especially on dark clothes. You can see how silk screening is different from other ways:

| Feature | Screen Printing | Other Methods |

|---|---|---|

| Durability | High, stands up to lots of washing | Often not as strong |

| Vibrancy of Colors | Very good for bright, bold pictures | Usually less colorful |

| Cost-Effectiveness | Good for big orders | Not always good for bulk |

| Fabric Compatibility | Works on many types of fabric | Only works on some materials |

Your prints will not fade or crack easily. Many artists and companies use silk screening for custom shirts because the designs stay fresh.

Versatility in Application

You can use silk screening on lots of different things. This makes it popular in many jobs. You might see silk screened art on shirts, bottles, metal signs, or wood. Here are some ways people use it:

- Big silk screening works on fabric, vinyl, wood, glass, and metal.

- You can make custom shirts, signs for events, and special products.

- Many jobs use silk screening, like stores, technology, defense, and art.

| Industry | Common Uses |

|---|---|

| Medical | Medical tools, medicine bottles |

| Food and Beverage | Drink bottles, home products |

| Retail | Glasses with logos, beauty items |

| Aerospace | Many uses |

Silk screening works for many needs, from clothes to technology.

Cost-Effectiveness for Large Runs

You save money when you print a lot at once with silk screening. Setting up takes time, but after that, you can make many items fast. This is smart for big orders, like team shirts or event clothes.

| Evidence Type | Description |

|---|---|

| Cost-effectiveness | Silk screening saves money for big jobs. |

| Process Complexity | It uses easy steps and simple tools. |

Tip: If you need hundreds of prints, silk screening helps you spend less and still get good quality.

Silk screening works best for simple designs and big batches. This way, you get bright, strong prints on many materials. That is why businesses and artists like it.

Silk Screening vs. Other Methods

Digital Printing Comparison

You might ask how silk screening is different from digital printing. Both ways let you make custom designs, but they work differently. Silk screening puts thick ink on top of the material. This makes the print feel raised when you touch it. Digital printing sprays ink right onto the surface. This makes the print smooth and flat.

Here is a table that shows the main differences:

| Aspect | Silk Screening | Digital Printing |

|---|---|---|

| Print Quality | Durable, vibrant colors | High-resolution, but less texture |

| Production Efficiency | Higher setup time, better for large batches | Quick setup, best for small orders |

| Texture | Tactile, raised ink | Smooth, modern look |

| Ideal Use Cases | Merchandise, posters, fine art | Custom designs, short runs |

Tip: Pick silk screening if you want a print that lasts and feels special. Digital printing is good for small orders or one-of-a-kind items.

Heat Transfer and Other Techniques

You might also see heat transfer used for custom prints. This way uses heat to press a design onto fabric. The print feels different than silk screening. Heat transfer prints can feel plasticky and are not as breathable. Silk screening gives a soft and comfy finish.

Compare the two methods in this table:

| Technique | Tactile Quality | Color Vibrancy |

|---|---|---|

| Silk Screening | Soft, breathable, textured | Bright, thick, and long-lasting |

| Heat Transfer | Plasticky, less breathable | Accurate colors, but less saturated |

Silk screening is special for a few reasons:

- You get bright colors that stand out, even on dark fabric.

- You can print on many things, like fabric, wood, and glass.

- You save money when you print a lot at once.

| Advantage | Description |

|---|---|

| Vibrant Colors | Bright, bold colors that show up well, even on dark materials |

| Suitable for Various Materials | Works on fabric, wood, glass, and more |

| Cost-Effective for Large Runs | Gets cheaper when you print more items |

Note: Many artists and businesses choose silk screening because it feels unique, has bold colors, and works well for big orders.

You see silk screening as a process that gives you bold colors, textured prints, and a hands-on experience. Artists like Andy Warhol made silk screening famous during the Pop Art movement. Modern machines now make silk screening faster and easier for everyone. You can use silk screening for art or for making many products. This method stays popular because you get creative control, strong results, and cost savings for big projects.

Silk screening remains a top choice when you want prints that stand out and last.

FAQ

What materials can you use for silk screening?

You can use silk screening on many materials. These include cotton, polyester, paper, glass, wood, and metal. You should choose the right ink for each material to get the best results.

How many colors can you print with silk screening?

You can print as many colors as you want. Each color needs its own screen and layer. Most designs use up to six colors for easy setup and clear images.

How do you care for silk screened prints?

Wash your silk screened items inside out with cold water. Use mild detergent. Avoid bleach and high heat. This helps your prints stay bright and last longer.

Is silk screening good for small orders?

Silk screening works best for large orders. The setup takes time. For small orders, digital printing may be faster and cheaper.